-

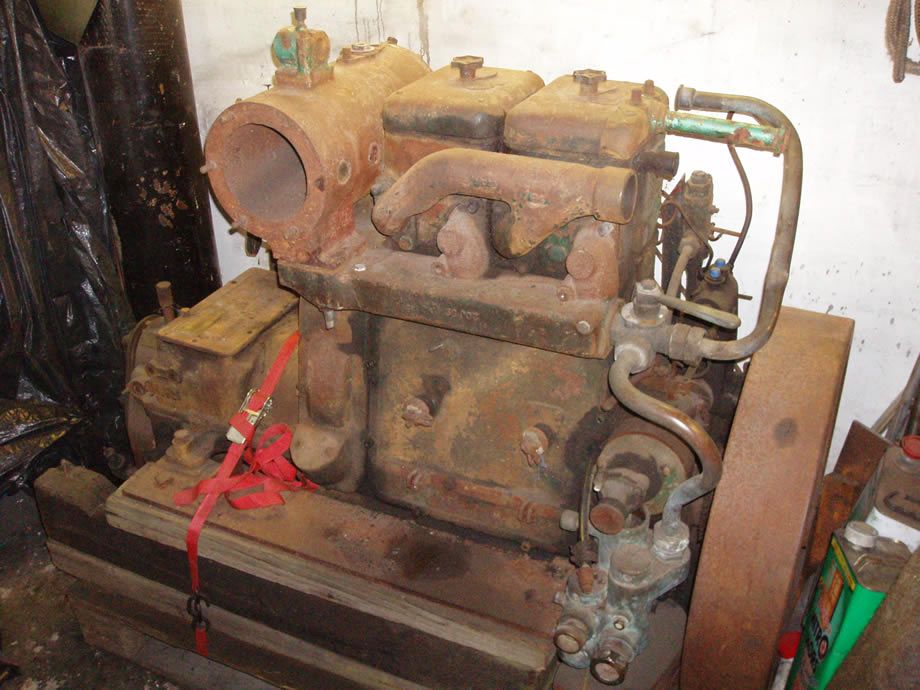

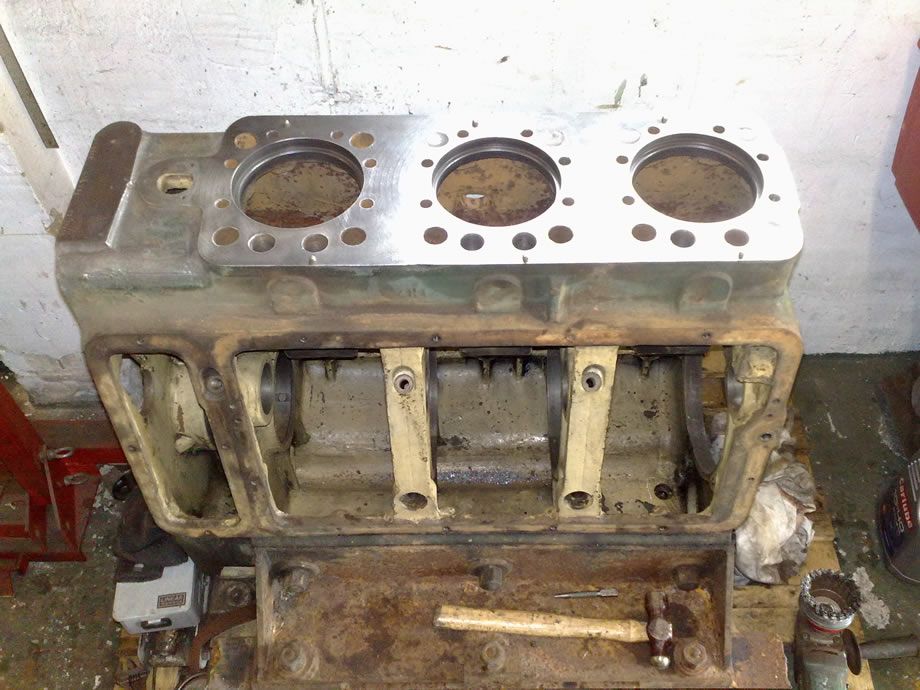

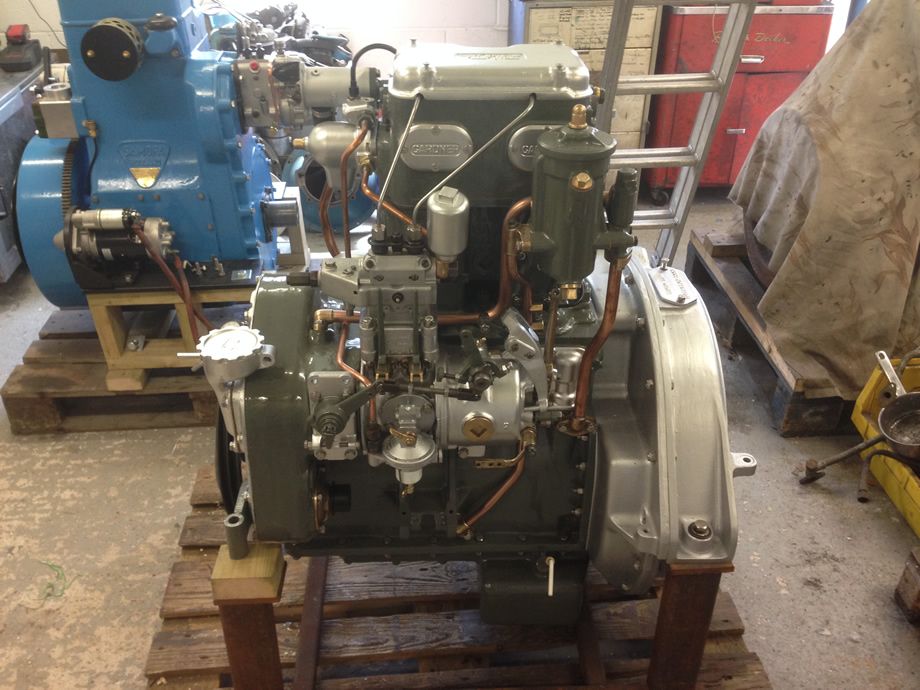

Gardner 2LW Before Restoration

-

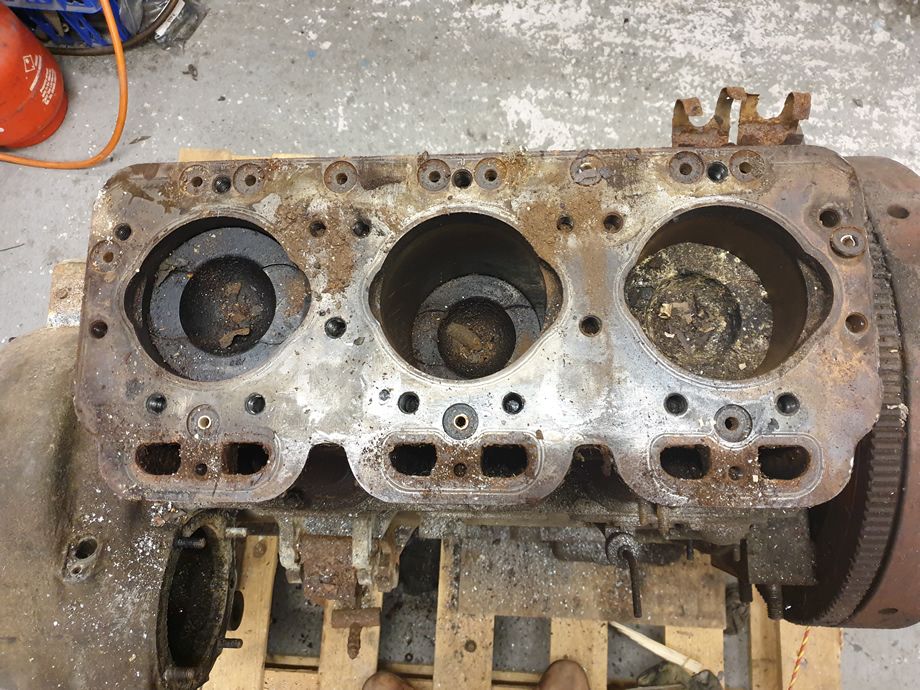

Lister JS3M Before Restoration

-

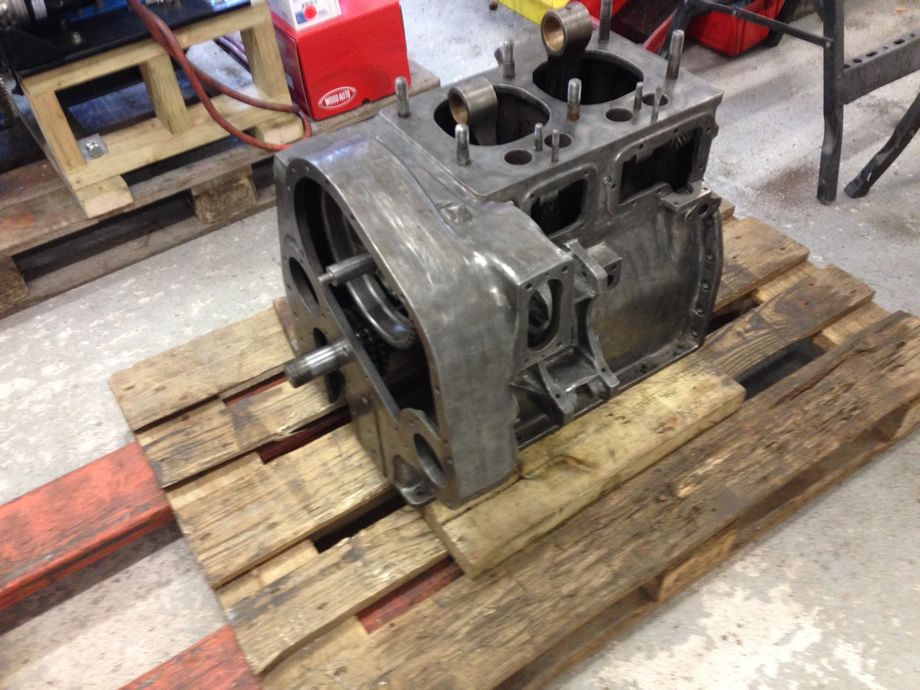

Lister JP2M Before Restoration

-

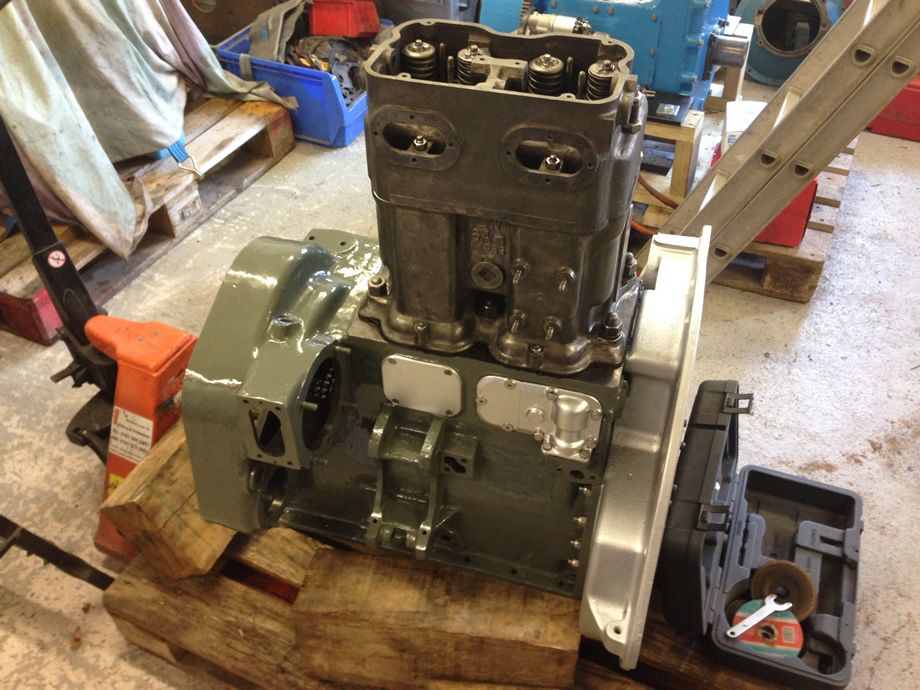

Dorman 3LB Before Restoration

We are often asked: what do we do to our engines?

This is simple enough to answer because we only classify engines under two categories, which are restored and used engines. By default all our engines are used but the restored ones have been subjected to a “down to the last nut and bolt rebuild”. The process we follow with all our restored engines is the same whether it is one we have supplied or a customers engine in for another lease of life. We believe our process is second to none and will ensure a reliable vintage engine which will provide many more years of service.

The first thing we do to any engine that comes in to us is assess its condition and if appropriate, attempt to run it. We learn a lot about each engine by the way it performs (or doesn’t) and the results often give pointers as to what to expect when it is stripped down. If it is an engine for our stock it is at this point that the initial decision is made (restore or suitable for sale as used).

-

Kromhout Gardner 3LW During Stripdown

-

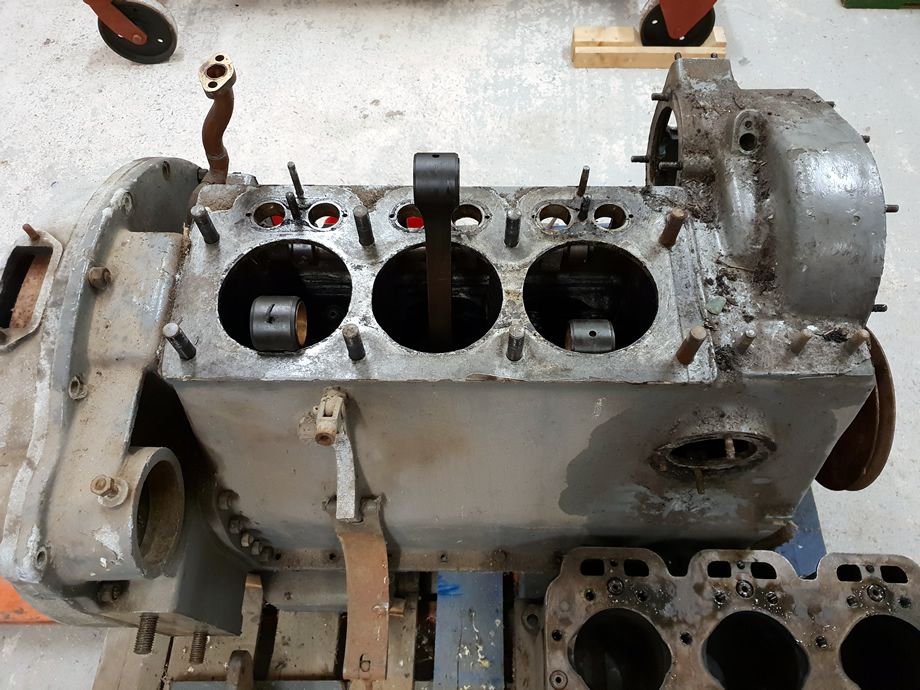

Kromhout 3LS During Stripdown

-

Lister JP3 During Stripdown

-

Gardner 6LX Sump During Stripdown

Stripdown & Inspection

With any engines that have joined the "for restoration" queue we dismantle the engine to its component parts whilst carrying out an initial examination of all the components for damage or wear that renders them beyond further use. The engine components are then subject to intensive cleaning including pickling in a caustic solution, degreasing in our chemical hot washer, blasting and power brushing. All the oil ways are cleaned and blown out. Every threaded hole in the engine is cleaned using the correct taps. All nuts and bolts are either replaced or cleaned and power brushed. Some components are sent for grit or shell blasting. It’s a lot of cleaning! Throughout all of this work we check each and every part of the engine for defects and general condition.

-

Kromhout Gardner 3LW Crankcase Before Overhaul

-

Lister JS3M Block Before Overhaul

-

Damaged Gardner Piston Found During stripdown

-

Gardner 3LW block before restoration

-

Kromhout Gardner 3LW Crankcase After Overhaul

-

Lister JS3M Crankcase After Overhaul

-

New MPS Produced Gardner Piston to Original Drawings

-

Gardner 3LW reconditioned block and new pistons

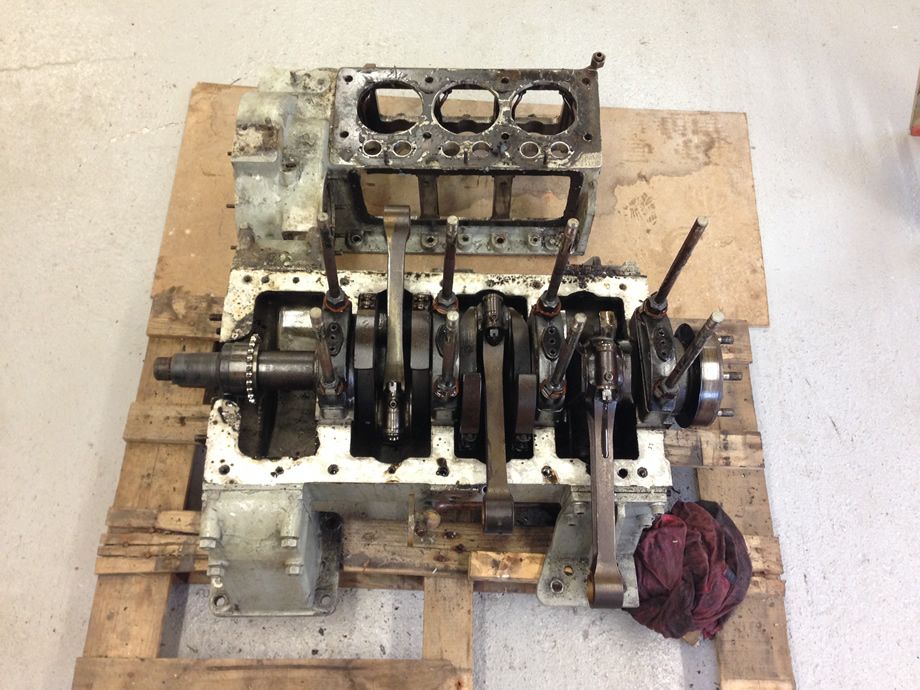

Component Overhaul

With any engines that have joined the "for restoration" queue we dismantle the engine to its component parts and immediately examine all the principal parts. The crankshaft and bearings will be sent off to our preferred specialist who will check against the original specifications and make the decision if regrinding or polishing is necessary. New shells, or on white metal bearing engines, re-metalling using virgin white metal and line boring follows. We pull all the cylinder liners out and check the block internals for corrosion, which is especially important for engines that have been used in salt water conditions. The cylinder liners, pistons etc are checked against the manufacturer’s data and replaced as necessary. All the fuel gear goes for reconditioning, as does the water pump and starter motor. The heads are stripped for valve and guide refurbishment as a matter of course. On Gardner and Kromhout models the cam box assembly is subject to a detailed strip and rebuild in every case. All roller, ball bearings and all lip seals are routinely replaced. On completion of any machining processes the components are subject to another intensive cleaning regime to ensure no debris is left behind with all oil ways cleaned and blown out. Every threaded hole in the engine is cleaned using the correct taps. All nuts and bolts are cleaned or replaced depending on condition. Some components are sent for grit or shell blasting. Throughout all of this work we again check each part for defects that may not have been apparent on initial inspection.

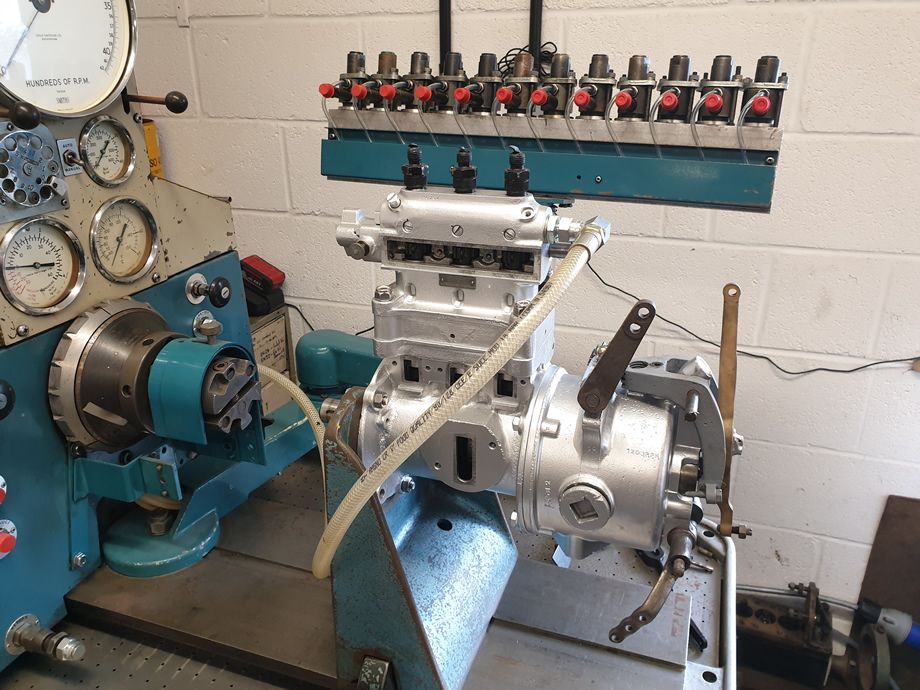

Fuel Injection Equipment

The classic engines we re-manufacture come from an era before engine emissions were of concern, but here at MPS we care about our environment and strive to ensure all our engines are as clean running as their design will allow, because of this all our fuel equipment is reconditioned in house on Hartridge test equipment to the original manufacturer specifications allowing us to ensure everything is set just the way it should be.

-

Gardner 2LW bare block awaiting rebuild

-

Gardner 2LW crank and camshaft re-fitted

-

Gardner 2LW block and head re-fitted

-

Gardner 2LW ready for test run

Assembly

The rebuilds are done to a build specification agreed with the purchaser (90% of our engines are bespoke). This may result in additions and alterations to the base engine to satisfy engine speed and power output requirements. The external piping is replaced as necessary. The adaptation work to fit a gearbox is achieved using a mix of proprietary parts and components to our own design. We close couple our gearboxes and do not bolt them to external plate mountings as some other restoration company’s do (This generally gives the benefit of a shorter engine installation). Alternators and auxiliary equipment are always extras and do not form part of a standard overhaul.

All our restored engines are subject to an engine enamel repaint and polishing and undergo test running and fine tuning before delivery. At every stage of the rebuild we take photographs of the work and can compile this into a cd with additional video footage for the new owner.

-

Gardner 2L2 During Test Run

-

Lister JS3M During Test Run

-

Gardner 2LW During Test Run

-

Dorman 3LB During Test Run

-

Gardner 6LX During Test Run (RNLI Build Spec)

Final Testing

On completion all our engines undergo a minimum of eight hours test running, during this time the engine is run to temperature, high and low idle speeds are set and final tweeks and adjustments are undertaken to ensure all is well.

All customers are welcome to attend the test running of their engine and a short video of each test run is recorded. This video along with a full photo album of the rebuild is supplied with each engine.

All our restored engines have a one year "from dispatch date" warranty

Customers often approach us to restore or recondition their existing engine. We are more than happy to undertake this work and the standard this is completed to is the same as all our engines. The engine is stripped and Inspected with a report provided. We do not do “rings and shells” overhauls or partial repairs. We are proud of our work, our name appears on the overhaul plaque on every restored engine we produce.

We sometimes get engines in that are in good order and not in need of heavy overhaul. These are sold as used serviced and repaired engines. These are subject to close inspection and servicing. We take the opportunity to carry out all necessary repairs, clean and repaint the engine. Such engines are ideal for customers who do not want the expense of a fully reconditioned unit and are happy with a good used engine at a fraction of the restored cost. These engines do not have a warranty other than a manufacturers warranty on any reconditioned or new parts we have fitted.

If you would like any further information on our restoration process or to discuss your needs, please feel free to contact us.